Our Past Projects

THERMAL SPRAY EQUIPMENT FOR TURBINE ENGINE COMPONENTS

CNC HONEYCOMB TACK WELD SYSTEM FOR AERO ENGINE COMPONENTS

HIGH END DRILLING SYSTEM FOR TURBINE COMPONENT COOLING HOLES

VACUUM FURNACES FOR TURBINE ENGINE COMPONENTS

Some facts

about us:

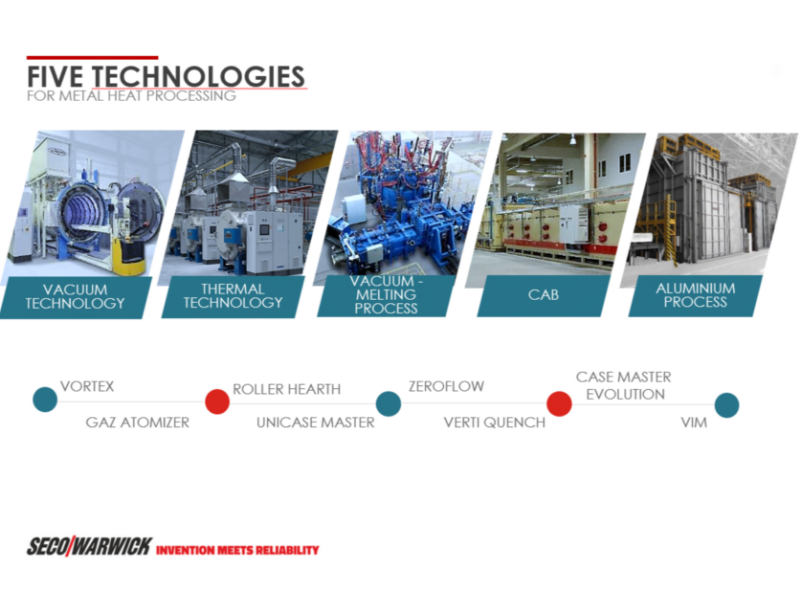

Heat Treatment Equipment

Tap on our range of high-quality heat treatment solutions for your metal heat processing.

With each project, we will work in tandem with the client to better understand their needs and from there, we will consult with experts on selecting the most optimum heat treating equipment.

Spanning across a wide array of industries including automotive, aerospace, energy, medical and military, our solutions comprise of fire resistance tests furnaces, vacuum equipment, heat treatment equipment, chambers for precision tests and many more.

Thermal Spray Equipment

Lincotek Equipment designs and manufactures bespoke coating equipment that utilises the most cutting-edge spraying solutions for thermal spray, which is a technology that improves or restores the surface of a solid material. This process can also enhance resistance to erosion, cavitation, corrosion, abrasion and heat.

Some of our thermal spray solutions include Air Plasma Spray (APS)—that creates quality and repeatable coatings using a wide range of materials, High Velocity Oxygen Fuel (HVOF) Liquid and Gas—to improve or restore a component’s surface properties or dimensions, and Vacuum Coating System (VCS)—which is designed for high-end applications.

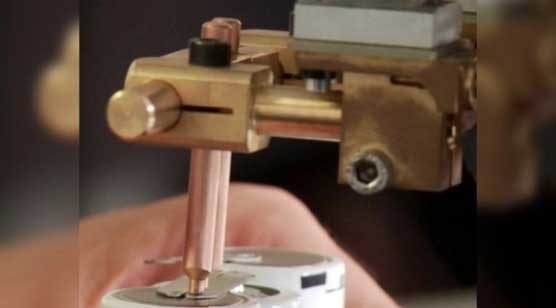

Micro-Resistance Welding

Expert in micro-welding since 1973, Soudax Equipements has been continuously designing and manufacturing micro-welding equipment, resistance welding and brazing equipment. Through its years of experience, Soudax has developed unique technology and know-how that allow for a wide range of France-manufactured equipment with the best possible welding quality.

When it comes to welding machines, there are mainly 2 types—AC welding and DC welding. AC welding systems are most commonly used to create seam welds using the continuous flow of energy from the AC power supply. Meanwhile, DC welding is ideal for extremely small and fine wire welding.

Some of our welding equipment include accumulator packs, honeycomb, ball tack welding, sintered materials, thermal protection and electrical relays.

High-end Drilling System

TEK4 offers a range of EDM hole drilling machines with world-leading performance and capabilities. These machines are specifically developed for hole drilling of aero, industrial gas turbine blades, vanes, segments, and other components.

TEK4s 6G machines are the latest generation of fast hole drilling EDM machines, which feature many new technologies and systems, including a completely new control system, through-flushing tooling, and drill after coating (DAC) technology.

We also offer Hydrothermal Spallation Drilling (HSD), a method that is ideal for drilling through hard and brittle rocks that are usually found in deep wells.

CF Global Difference

Broad Assortment of Quality control Equipment

Technical Assistance on

Every Purchase

Brand Neutral & Independent - Allowing us to be customer & application focused

Competitive Pricing Coupled with High Standards